Imported yard ramps have not been a significant factor in the USA yard ramp market. However I have seen a large number of requests from foreign manufacturers that want us to import and market these yard ramps. That is not surprising because we are the largest retailer of yard ramps in the USA and these foreign manufacturers want to have a portion of that market share. We have had discussions with several manufacturers who offered to make yard ramps for us. The pricing was very attractive unfortunately the products offered by these foreign manufacturers were not up the durability and safety standards that we require.

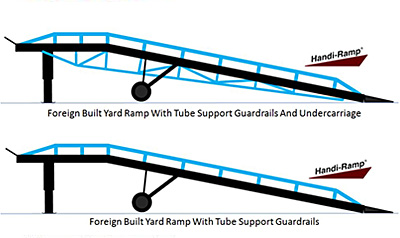

Since some resellers of yard ramps may not tell you that they are selling a foreign built yard ramp you will need to know how to identify a foreign built yard ramp. Yard ramps that are manufactured overseas are relatively easy to identify since they have a similar look and feel. Most commonly foreign built yard ramps use an independent guard rail and/or support structure as shown in the line drawings to the right. The Made in America yard ramps typically use a solid support side rail structure and these super structure side beams function as guard rails. Other common features of imported yard ramps include hinged approach ramps and hinged or limited structure transition lips. We will discuss these features in more detail in the following sections.

Since some resellers of yard ramps may not tell you that they are selling a foreign built yard ramp you will need to know how to identify a foreign built yard ramp. Yard ramps that are manufactured overseas are relatively easy to identify since they have a similar look and feel. Most commonly foreign built yard ramps use an independent guard rail and/or support structure as shown in the line drawings to the right. The Made in America yard ramps typically use a solid support side rail structure and these super structure side beams function as guard rails. Other common features of imported yard ramps include hinged approach ramps and hinged or limited structure transition lips. We will discuss these features in more detail in the following sections.

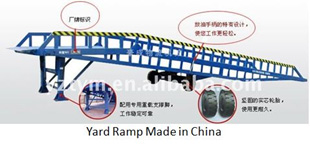

Most foreign built yard ramps are coming out of China but we have also seen a few coming out of Korea. Distributors may not advertise the country of origin and some will actually lie about it. Here are some pictures of some typical yard ramp designs.

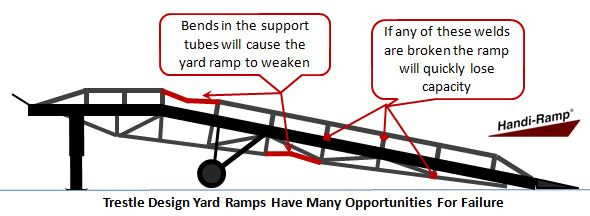

There is one primary factor that determines the capacity of a yard ramp: The strength and capacity of the side support beams. The side support beams or in the case of the China yard ramps the side support structure must support the entire capacity of the load. The Made in the USA yard ramp typically has a single super structure beam that has been designed to support the designated capacity of the yard ramp. In the yard ramp imported from China the main support beam does not have the capacity to support the designated load so they add support and capacity by welding tube onto the side beams. Both yard ramps will have the same capacity when they leave the factory. However during daily use the ramp from China must be handled with care. The welded tube supports must not be damaged or weakened in any way because if one of the supporting tubes is bent or the welds are broken the remaining beam does not have enough structure for the original capacity.

The imported yard ramp design (small side beam with welded tube supports) is similar to the trestle type structure used on many bridges. This design can be very strong but it is used on fixed structures because if any of the supporting trestles are damaged or welds are cracked the yard ramp will no longer have the structural integrity to support the expected weight capacity.

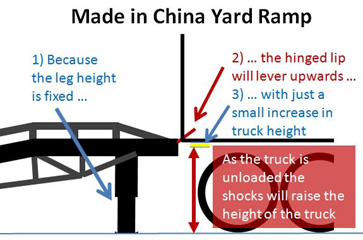

The operational design of the imported yard ramp is flawed. The hinged lip design combined with a fixed leg and hydraulic wheel assembly makes the imported yard ramp more complicated to set up and creates a safety problem when it is used to unload a truck. When setting up this yard ramp you must first position it behind the trailer, then raise it to the right height with the hydraulic pump and finally use a crank to set the fixed leg to the right height for each truck.

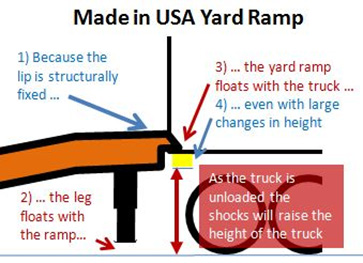

This design becomes a problem when a forklift adds or removes a pallet from the trailer. Trailers have their own suspension systems so when the trailer is unloaded or loaded the height of the trailer will rise or fall. In fact the height of the trailer will change simply as a result of moving a forklift from the ramp to the trailer. When this happens there is a risk to the hinged lip of the yard ramp and to the forklift if it catches on the yard ramp.

The picture to the right depicts how the position of the hinged lip will change as a trailer is unloaded. What happens is that the lip will be levered upward as the trailer is unloaded, becoming lighter and rising up. When the trailer raises the hinged lip which is resting on the edge of the trailer will become angled up with very small changes in the height of the trailer. When the hinged lip is angled upward like this the forklift will either bend the lip, break the hinge or the forklift could get caught up on the raised lip. The only way to prevent this from happening is to adjust the height of the fixed leg on the yard ramp after each pallet is moved either up or down the yard ramp.

Compare this to the traditional yard ramp made in USA which uses a fixed lip structure. This design literally enables the yard ramp to float with the height of the trailer. If the trailer rises or falls then the yard ramp will rise or fall. Simple design, simpler implementation.

Imported yard ramps use a hinged approach ramp design. These approach ramps have three major problems: First, these ramps are heavy and they require someone to hand deploy them. Because of the size and the weight of these approach ramps they could easily be dropped on someone’s foot result in a serious injury. Second, the approach ramp has a smooth metal surface with expanded metal wire welded onto this surface for traction. The expanded metal wire is not heavy duty and will certainly rust out within a couple of years. This expanded metal wire will have to be replaced at that time. Third, using a hinge on these approach ramps when none is required adds complexity. The hinge could be damaged, rust or fail. The made in America yard ramp design makes the approach an integral part of the solid structure of the ramp. I cannot see any operational advantage with a hinged approach ramp. Simple is better.

Imported yard ramps use a hinged approach ramp design. These approach ramps have three major problems: First, these ramps are heavy and they require someone to hand deploy them. Because of the size and the weight of these approach ramps they could easily be dropped on someone’s foot result in a serious injury. Second, the approach ramp has a smooth metal surface with expanded metal wire welded onto this surface for traction. The expanded metal wire is not heavy duty and will certainly rust out within a couple of years. This expanded metal wire will have to be replaced at that time. Third, using a hinge on these approach ramps when none is required adds complexity. The hinge could be damaged, rust or fail. The made in America yard ramp design makes the approach an integral part of the solid structure of the ramp. I cannot see any operational advantage with a hinged approach ramp. Simple is better.

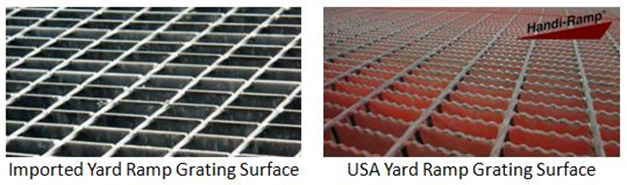

The surface of the grating used in the imported yard ramps that we reviewed claimed to be serrated but closer examination reveals that this is not true. A comparison of the grating surfaces shows the difference. The USA grating has serrations while the imported grating does not. Most forklift tires are smooth and they will slip on the sooth grating surface shown on the left if the yard ramp were to become even the slightest bit wet.

Every forklift driver needs to be trained to properly use a forklift ramp. The design of the guard rails and lip system on the yard ramps imported from China do not provide the safe guards that should be in place. The picture on the right shows a yard ramp and the guard rails look to be simple tube that will not provide much in the way of support should the forklift bump into them.

Ready to purchase your American-Made Yard Ramp?

Give our experts a call today at 1-800-876-RAMP